When you Google “metal tobacco pipe” you are inundated with pages and pages of marijuana smoking pipes with very few references to actual classic tobacco pipes made fully or partly with metal parts. But, if you look really hard you will find rare references to the almost cult-like segment of traditional tobacco pipes known as “Metal.”

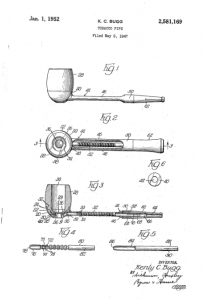

In 1936, an American engineer, Kenley Bugg of Ft. Wayne, Indiana designed what would be a revolutionary take on the classic tobacco pipe. Patented in 1945, Bugg’s marriage of metal and briar, promised a more pleasant smoking experience. Here’s an excerpt from Bugg’s patent application…

Among the objects of this invention are:

(a) To provide a pipe of relatively simple construction, having very desirable smoking properties, an attractive appearance, and a suitable weight and feel.

(b) to provide a pipe which has a simplified bowl construction without an integrally formed stem portion, but which is capable of being readily assembled with a removable stem so that a firm and positive engagement is provided between the two components.

(c) To provide a tobacco pipe having a construction such that even combustion of much of the entire load of tobacco is insured.

(d) To provide a tobacco pipe in which the bowl and stem, when assembled, form a novel passageway for the smoke that insures against clogging and the undesirable entry of moisture into the stem.

(e) To provide a bowl and stem construction which will insure against the freezing of these two components in assembled relation, but which will provide a seal there between which insures against the leakage of fluids into areas where there presence is undesirable.

(f) to provide a tobacco pipe which has components that are not only readily disassembled, but lend themselves to being readily disassembled, but lend themselves to being readily cleaned with a minimum of effort.

(g) To provide a tobacco pipe comprising three basic components of simple design and construction which are very readily and economically manufactured.

U.S. Patent No. 2,581,169 to Bugg describes detachable bowl pipes in which the bowl holder (metal stem assembly) carries a Condensing Plug which extends upwardly into the opening in the bowl so that a narrow annular smoke passage is left between it and the bowl opening. The smoke passing over the surface of the condensing plug is cooled and the water vapor in the smoke condenses in the bowl holder, resulting in a drier and more comfortable smoking experience. Armed with his patent, Bugg approached George L. Hunt of Diversey Machine Works in Chicago to produce what is now known as the Falcon Pipe. By 1954, Falcon had sold over six million of their pipes in the United States alone (that’s roughly 11.3% of adult American males according to population counts.)

As an engineer, almost assuredly, Bugg’s goal for his design was based on utility and not art. Using metal would be imperative if Bugg was going to decrease the tongue biting presence of hot water vapor and harmful tar in his pipe’s smoke.

In 1958, Falcon began selling overseas. Sometime in the early 1960’s, production moved to England. A couple of years after their introduction to the British markets, a poll showed that 40% of established pipe smokers in Britain owned a Falcon and that these same smokers purchased a Falcon more than 50% more often than any other brand of pipe. By 1974, Falcon London had sold more than fourteen million Falcons outside the United States.

So, as you can see, the marriage of metal and briar has a substantial backstory rooted in good old American engineering, manufacturing and marketing taken to a worldwide audience.

I’M NOT INTERESTED IN “THAT” STYLE PIPE!

What is it that causes a hugely popular product to all but disappear from the market? Why are these modern metal fitted pipes so hard to find in your typical pipe shop showcase? There’s probably several answers, but the main reasons are lack of passion by those still running Falcon, which spearheaded the medium for decades, the fact that metal is a much more difficult medium for artisan pipe makers to successfully work with in garage workshops. Additionally, the changing opinion of consumers that metal pipes are flimsy, cheap and thus embarrassing to be seen smoking. The metal pipe has fallen off the radar of most of today’s tobacconists because they lack the passion for the benefits of the design. And, the pipe smoking market has shrunk substantially over the last 40 some odd years due to a general exit from the consumption of all tobacco products led by anti cigarette smoking efforts.

The typical pipe maker that has a passion for the medium needs to invest a lot more effort into making even one metal pipe. While just about anyone with a pocket knife could fashion a pipe out of briar, very few of us have the machinist skills to make metal stems that will stand the test of time. It takes a bit more commitment and passion to begin an artisan metal pipeworks. But, even though there are still only a handful of pipe makers working with metal as more than just a decorative accent, those that are committed to this craft are producing some fantastic new pipes.

Falcon and its imitators were marketed specifically to a low price point buyer. Their use of aluminum for their frames and lack of high-end finish obscured the fact that, although value priced, the available bowls could range from very cheap to extremely high end. This snobbery due to the typical price has clouded the impact of the design benefits for most modern pipe smokers. And, unless consumers are introduced to a metal pipe by a tobacconist with passion for the design, they are usually passed over as “toys” at best.

Probably, more important than any single other reason for a decline in both traditional and metal pipe demand lies in the fact that the vast majority of people can’t / don’t smoke at work anymore. Add to that the pervasive lack of indoor smoking of any kind at home (gone are the days where the living room smelled like grandpa’s pipe smoke) and we are left with a hobby that can only be enjoyed in the narrow space of our “spare” time in an outdoor setting.

The best hope for an increase in interest for metal pipes lies in the hands of artisan pipe designs and passionate evangelical tobacconists. The “cheap” cardboard mounted display of Falcons won’t motivate today’s discerning consumer any more than the corn cob pipe (also mistakenly overlooked) does. High end presentation and styling will open more doors than innovative smoke cooling design in today’s market.

TODAY’S METAL PIPES

Necessity was the mother of invention when it comes to the birth of metal pipes. Guys that smoked their pipes all day long had the wish for a cooler and dryer smoke. They combined their desire with engineering skills to design what we know today as the metal tobacco pipe. While it’s very hard to find a job that will let you smoke your pipe while you work today, there are still some of those guys and gals out there bringing both forgotten innovation and exquisite design to pipes.

FALCON LTD

While Falcon Pipes are still available, as they have been since the 1940’s, there are several committed artisans pushing the design envelope in combining metal, briar and even meerschaum to support the Falcon product. There’s an entire cottage industry committed to creating compatible bowls for Falcon pipes. Meanwhile, other than a few color changes, today’s Falcon is exactly the same as one made in the 1940’s, 50’s, or beyond.

H. WIEBE

Canada’s Hekthor Wiebe, out of Winnipeg Manitoba, has a growing line of metal meets briar pipes he’s named The Radiator. H. Wiebe pipes offer a much higher end presentation with their most popular model featuring a bent design that is guaranteed to start conversations.

Wiebe considers himself to be 100% engineer first and artist a distance second although I don’t think he gives himself enough credit as his pipe designs are quite eye catching.

TSUGE

Japanese pipe maker Ken Tsuge has been bringing various materials such as metal, briar, bamboo and others together to produce some of the most beautiful modern pipes in the world for years. Ken partnered with Jonathan Drew and Drew Estates to bring three great Drew Estate specific designs to the US in 2014. Unfortunately, Drew discontinued their entire pipe business in 2017/2018, but there are still some great examples out there to be had.

KIRSTEN PIPES

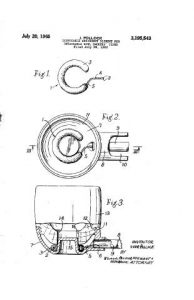

Seattle-based Kirsten actually was created the same year as Falcon, 1936. German born engineer Professor Frederick K. Kirsten came to the US in 1902 as a cabin boy on a merchant ship. After rounding Cape Horn and experiencing the rough and tumble of ports in Asia, Kirsten jumped ship in Seattle and started a new life in the Pacific Northwest.

On the advice of his doctor to switch from cigarettes (not give up, but switch — times have changed,) Kirsten took up pipe smoking. Being an engineer, he set out to develop a new pipe that would trap the moisture, tars and tongue-biting acids which attack the users of standard pipes. Over eighty years later, the Kirsten family still produces (sometimes, when they can find a good machinist) Professor Kirsten’s designs.

MISCELLANEOUS OFFERINGS

As with just about everything else in life, there are people out there that copy a good idea. Some imitators do a great job on innovating the design, creating works of smokable art along the way. Some do just a serviceable job at best in their quest to enter the lowest end of the market based solely on price.

Over the 85+ years that have passed since Falcon / Kirsten popped into the minds of their creators. Their groundbreaking metal pipe designs inspired hundreds of metal pipe manufacturers that have come and gone over the years. You can delve into the history of metal pipes at Tony Pringle’s SMOKING METAL website, where he has painstakingly cataloged metal pipes in a detailed review that only comes from someone that truly loves his hobby.

Doug Bisbee of dK Metal Pipes in Florida, is an expert at restoring and modifying the metal pipes from the past. Doug is a dedicated craftsman with over 30 years experience as a metal polisher, who loves smoking metal tobacco pipes. He has combined these 2 passions into dk Metal Pipes.

While, there are still several passionate artisans out there making metal and metal / briar combinations with beautiful results, the manufacture of the metal tobacco smoking pipe is a fairly rare experience these days.

THE FUTURE WITH THE FDA REGULATION & FLAVORED TOBACCO BANS

At this moment, February, 2021, there are two governmental threats to the hobby of pipe smoking. FDA Deeming Regulations / Federal legislation and flavored tobacco bans.

FDA Deeming Regulations with respect to tobacco products have classified tobacco pipes as a regulated tobacco product. As of August 8, 2016, any new pipe makers or pipe designs will need to earn prior approval BEFORE they can sell their pipes to consumers. No one has actually gone through this process, so we don’t really know how onerous the review will be. What we do know is that it’s going to take quite a bit of time and commitment for anyone that wants to bring a new pipe to the market. Even with an “easier” process for artisan pipe makers included in the regulation, it’s still quite a bit of work for a guy that is dreaming up something beautiful in his garage workshop.

AND! the FDA’s reach even extends to repair / refurbishment of pipes. Basically, any human, other than the owner of the pipe, that does any work on an existing pipe is considered a manufacturer and subject to onerous regulation.

Still others will be trapped in the limbo area between February 15, 2007 and August 8, 2016. While an untold number of new pipes and pipe makers have entered the market during that period, they will all have to be retroactively approved by the FDA if they wish to continue to sell pipes after the stipulated date of August 8, 2018.

Flavored tobacco bans are putting pipe smoking in peril by making the sale of any tobacco product with a “characterizing flavor other than plain tobacco” illegal. While the target of these bans is underaged vaping and candy flavored cheap cigars, if an exclusion for premium pipe tobacco is not carved-out when the law is implemented, the sale of all AROMATIC and ENGLISH style pipe tobaccos may be banned, leaving just a handful of NON-AROMATIC tobaccos as the last vestiges of a centuries long pastime. That fond memory of the scent of your Grandfather’s cherry pipe tobacco will end with you.

The spark of a resurgence and renaissance of pipes we’ve been seeing over the last several years may be snuffed out by a process that requires a simple tobacco pipe maker to go through the work and expense that a major pharmaceutical company does to get a piece of medical equipment approved.

In terms of the metal pipe movement, the FDA regulations could consolidate the market back to the point pre 2007 manufacturers where Falcon and Kirsten, are the only grandfathered metal pipe models available if there is no regulatory or judicial relief.